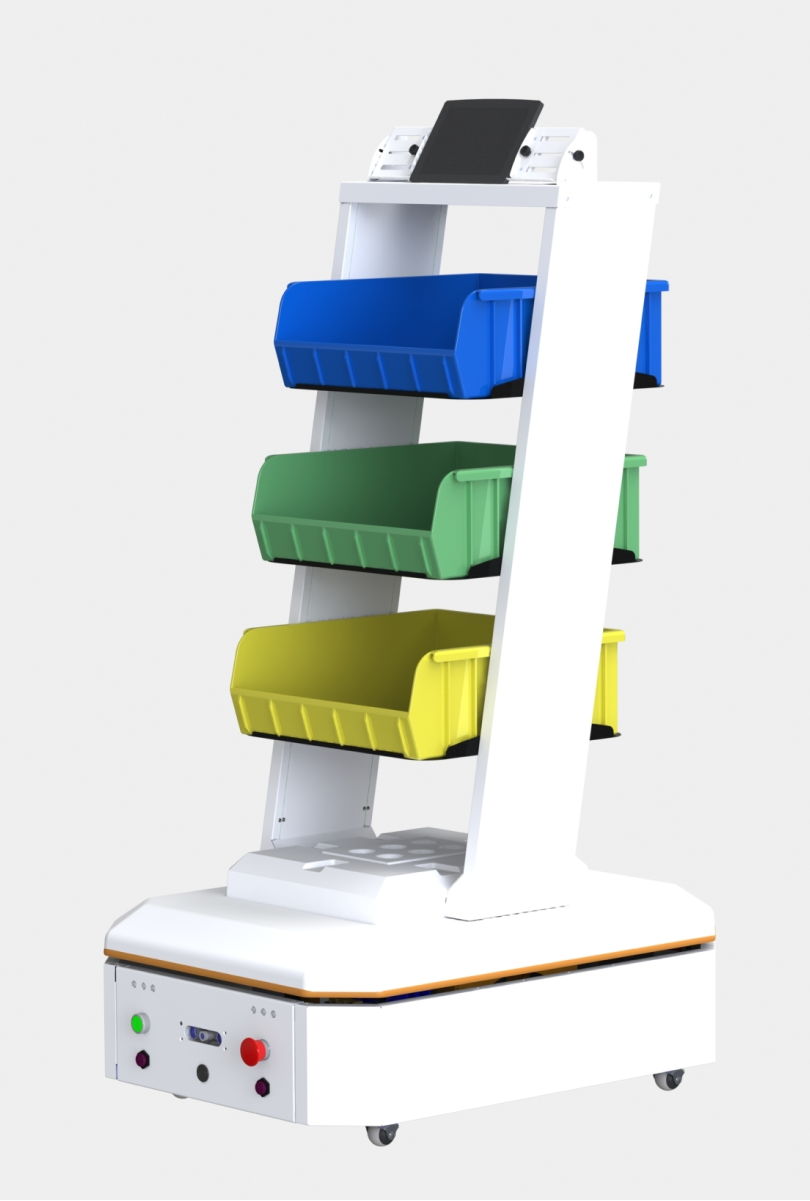

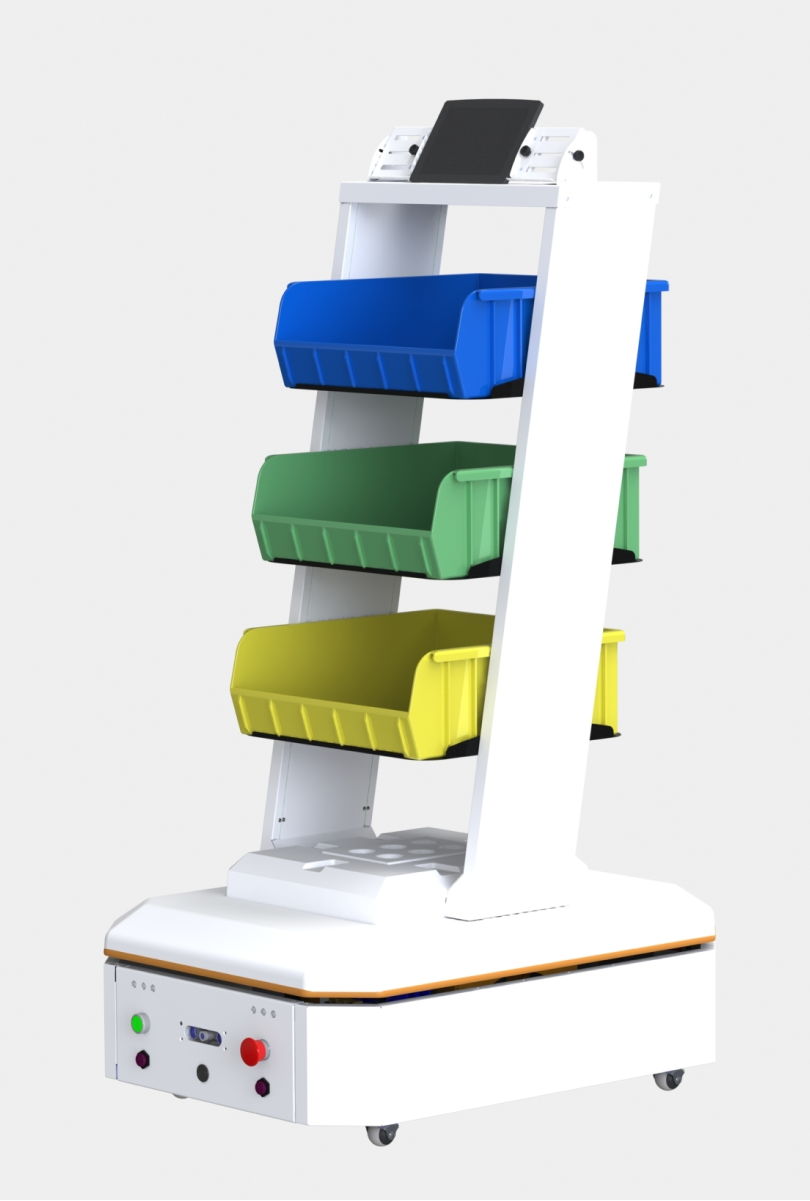

retail fulfillment amr

- 3x IMPROVES WORKER PRODUCTIVITY

- 3X ENABLING HIGHER PICK RATES

- 30% LOWER LABOR COSTS

- SIMPLE USER INTERFACE

We are a robotics and automation company specializing in affordable, modular, and intelligent solutions for last-mile delivery, e-commerce, e-grocery, CEP (Courier, Express, Parcel), and SME manufacturers.

Our mission is to bridge the gap between scalable robotics technologies and small-to-medium-sized businesses through deep-tech innovation, open-source development, and hands-on education.

Our custom-designed robots are both affordable and user-friendly, making them an ideal choice for automating simple intralogistics operations. Unlike larger fleet management systems, our robots require minimal oversight and can be easily tailored to the needs of small and medium-sized manufacturing enterprises.

We pride ourselves on our ability to offer affordable solutions that don't compromise on quality. To that end, we work closely with our partners at Bosch Rexroth incorporating their top-of-the-line components into our robots.

ELIMINATES WASTED WALKING TIME.Higher productivity, less aisle traffic

Robot-centric environments low human interaction

easily reconfigurable

By automating these simple logistics processes using affordable mobile robots, manufacturing SMEs and warehouses can achieve greater efficiency, accuracy, and productivity, while reducing the risk of errors and improving safety.

Botshare Team streamlines logistics processes with cost-effective mobile robotics solutions for SMEs. Our AI-based cloud services and cognitive robots simplify deployment of automation, while RaaS model lowers the entry barrier.

By implementing AMR automation, warehouses have reported up to 50% increase in productivity and up to 30% reduction in labor costs. In addition, AMRs can help reduce the need for manual labor and improve inventory accuracy, resulting in more efficient use of warehouse space.

Manufacturing enterprises have reported up to 20% increase in productivity and up to 50% reduction in labor costs with the use of AMRs for material handling tasks. By automating these tasks, AMRs can also reduce the risk of injury and improve overall safety in the workplace.

By implementing AMR automation in hospitality and restaurant settings, businesses have reported up to 30% increase in efficiency and up to 50% reduction in labor costs. In addition, AMRs can help reduce wait times for guests, improve order accuracy, and free up staff to focus on more complex tasks, such as customer service.

Hospitals have reported up to 40% increase in productivity and up to 30% reduction in labor costs with the use of AMRs for transporting medical supplies and equipment. In addition, AMRs can help reduce the risk of contamination and improve patient outcomes by ensuring timely delivery of critical supplies and medications.

Following the 6 principles we cover is the foundation of Botshare's Mission and sustainability strategy.

We cooperate with leading enterprises in our country and Globally on Win-Win based model. Our partners are Manufacturers, R&D institutions, leading robotics developers, governmental institutions - we learn from each other and growth together.